Table of Contents

Did you know that over 70% of consumers say packaging design influences their buying decision? Packaging isn’t just a box; it’s your product’s first impression, salesperson, and social media star all rolled into one.

Get it right, and your packaging can protect your product, boost your brand, and make customers fall in love before they even open the box. Get it wrong, and you’re fighting returns, complaints, and shelf invisibility.

TL;DR

- Great packaging protects your product, tells your story, and creates a moment your customers actually remember.

- Be sure to test it early under real-world conditions like shipping, climate, and handling.

- Keep visuals clear and consistent, and make sure your design works both on-shelf and on-screen.

- Factor in regional quirks like climate, regulations, and culture; they all affect materials and design choices.

- And remember: packaging can double as marketing when you build in storytelling, share-worthy details, and personality!

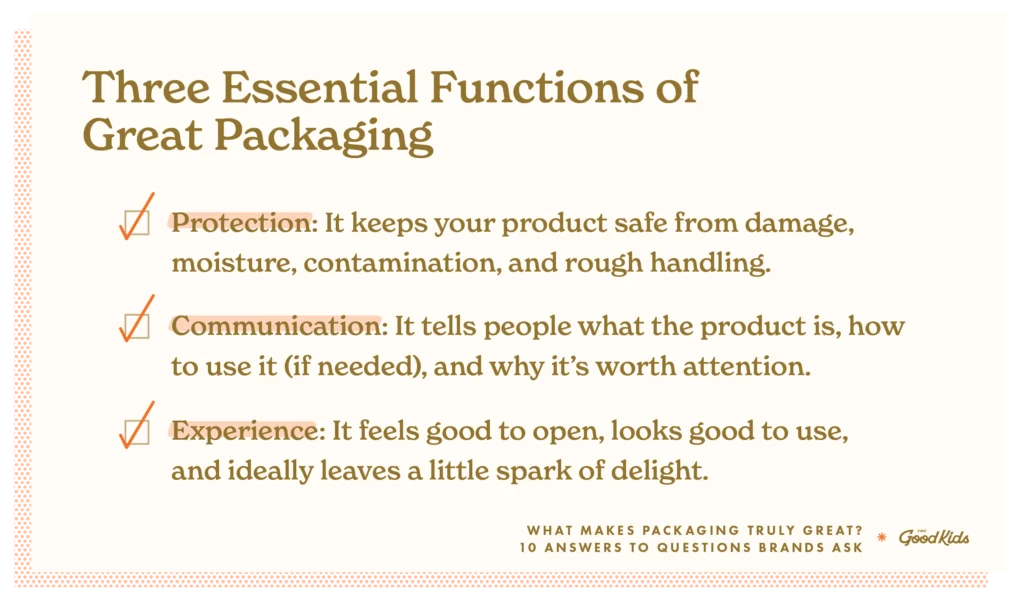

What are the essential functions packaging must serve?

At its core, great packaging nails three things:

- Protection: It keeps your product safe from damage, moisture, contamination, and rough handling.

- Communication: It tells people what the product is, how to use it (if needed), and what makes your brand worth caring about.

- Experience: It feels good to open, looks good to use, and ideally leaves a little spark of delight.

To pull that off, think ahead: What kind of stress will your packaging face (shipping, box stacking, climate)? Who’s touching it first (online shopper or in-store browser)? And what do you want the packaging itself to say about your brand? Should it exude sustainability, luxury, or playfulness?

How do I create packaging that reflects my brand identity?

Your packaging should feel like your brand at every touchpoint.

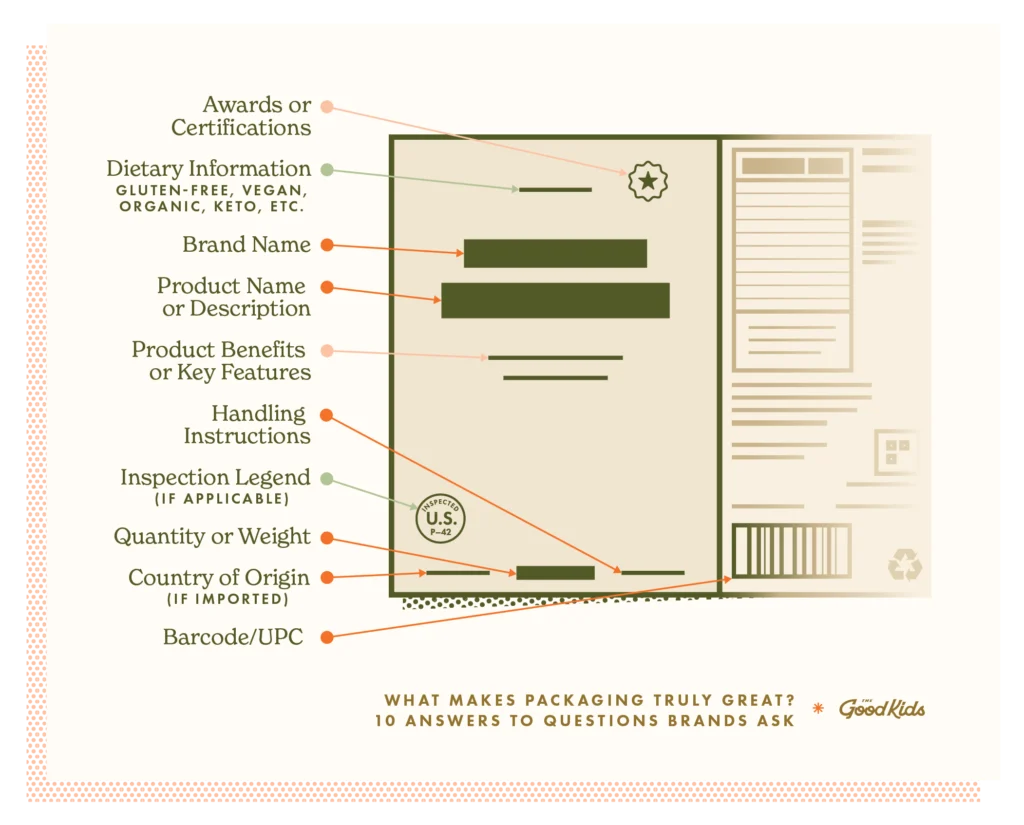

Use your established color palette and fonts. Consistency is always key.

Match your materials and finishes to your positioning. Luxury brands tend to go for textured paper, embossing, or metallic foils. Eco-minded brands lean toward natural fibers and recyclable materials.

Add small nods to your brand story; maybe a tagline, illustration, or hidden message that ties back to your values or origin story.

Even the architecture of your packaging should fit your brand. A “fun and playful” brand might use bold colors or surprising shapes. A “clean and professional” one might prefer minimal, structured design.

Ultimately, your product packaging should feel like an extension of your store experience, just delivered straight to the customer’s doorstep.

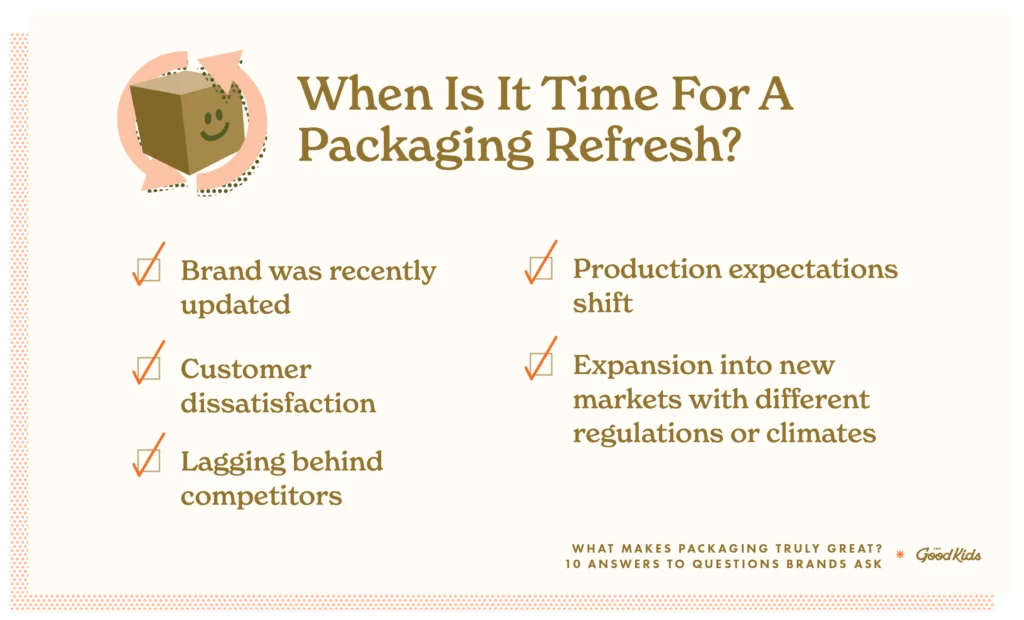

When and how should I redesign my product packaging?

Packaging isn’t a one-and-done deal. You’ll know it’s time for a refresh when:

- You’ve updated your brand identity; new logo, tone, or positioning.

- Customers report damage or dissatisfaction.

- Costs, materials, or sustainability expectations shift.

- You’re expanding into new markets with different regulations or climates.

- Competitors evolve and your look starts to lag behind

How can I make packaging sustainable without blowing my budget?

Sustainability doesn’t have to be expensive. Often, it’s about being clever, not costly.

- Choose recyclable, compostable, or biodegradable materials whenever possible; recycled cardboard, paper, or anything easy to recycle is a great start.

- Shrink your materials: smaller boxes, minimal inserts, and less padding. Less waste usually means less money, too.

- Ask suppliers about smart swaps whether it’s thinner board stock, water-based inks, compostable coatings. Even one small change can make a big impact.

- Consider modular or standard forms that work across multiple SKUs or sizes. It spreads out your tooling costs.

And don’t forget to tell your sustainability story right on the packaging. A small message or icon can go a long way in showing customers you care, and even justify a small premium.

What materials work best for different products and environments?

It depends on what you’re selling, and where it’s going.

Fragile items

Go for corrugated cardboard, molded pulp, or foam. Protect the inside before you worry about fancy exteriors.

Food or cosmetics

You’ll need food-safe, non-toxic, moisture and odor-resistant materials. Check regulatory requirements in your target regions (try databases like Enhesa).

Humid or hot climates

Use moisture barriers, sealed edges, and coatings that prevent warping.

Cold or frozen shipping

Prioritize insulation and moisture control (liners can help!).

Lightweight items

Opt for thinner materials or flexible packaging to keep shipping costs down while maintaining protection.

What visual design choices matter most in packaging?

Once the structure’s solid, visuals take the spotlight.

Typography

Prioritize legibility, online and in person. But remember to stay true to your brand guidelines!

Color

Use contrast to stand out and make sure printed colors match your digital designs.

Logo placement

Prominent but balanced. Big enough to be noticed, subtle enough to stay elegant.

Finishes

Embossing, foils, textures; they add dimension and luxury. Just make sure they don’t mess with recyclability.

Windows or see-through panels

Great for showcasing your product, but only if they don’t weaken protection or mislead buyers.

How do I balance cost, logistics, and aesthetics?

Every design choice has a trade-off; your job is to find the right balance.

- Tooling & die-cuts: Custom shapes are fun but pricey. Worth it for high volume, otherwise go standard.

- Shipping: Lighter, flatter packaging cuts freight costs; bulky or heavy designs can undo your savings fast. Be sure to look into USPS’s shipping prices to develop an understanding.

- Assembly: Complex folds or manual steps mean more labor costs. Simpler is usually smarter.

- Finishes & inks: Specialty options look stunning, but be strategic; make sure the upgrade actually drives perceived value.

- Order volume: Larger orders = better unit pricing.

Make a list of “must-haves” vs. “nice-to-haves.” Keep what strengthens protection, branding, or experience, and then cut the rest.

How do packaging regulations, climate & culture affect design in different regions?

One-size-fits-all doesn’t work for packaging.

- Regulations: Some regions restrict plastics or require specific labels (ingredients, safety, origin). Plan for compliance early.

- Climate: Hot? Avoid adhesives that melt. Cold? Guard against cracking. Humid? Seal it tight.

- Logistics: If roads are rough or storage unpredictable, your packaging needs extra durability.

- Culture: Colors, imagery, and luxury cues vary. What feels “premium” in one place can feel “cold” in another.

How should I test packaging before going into production?

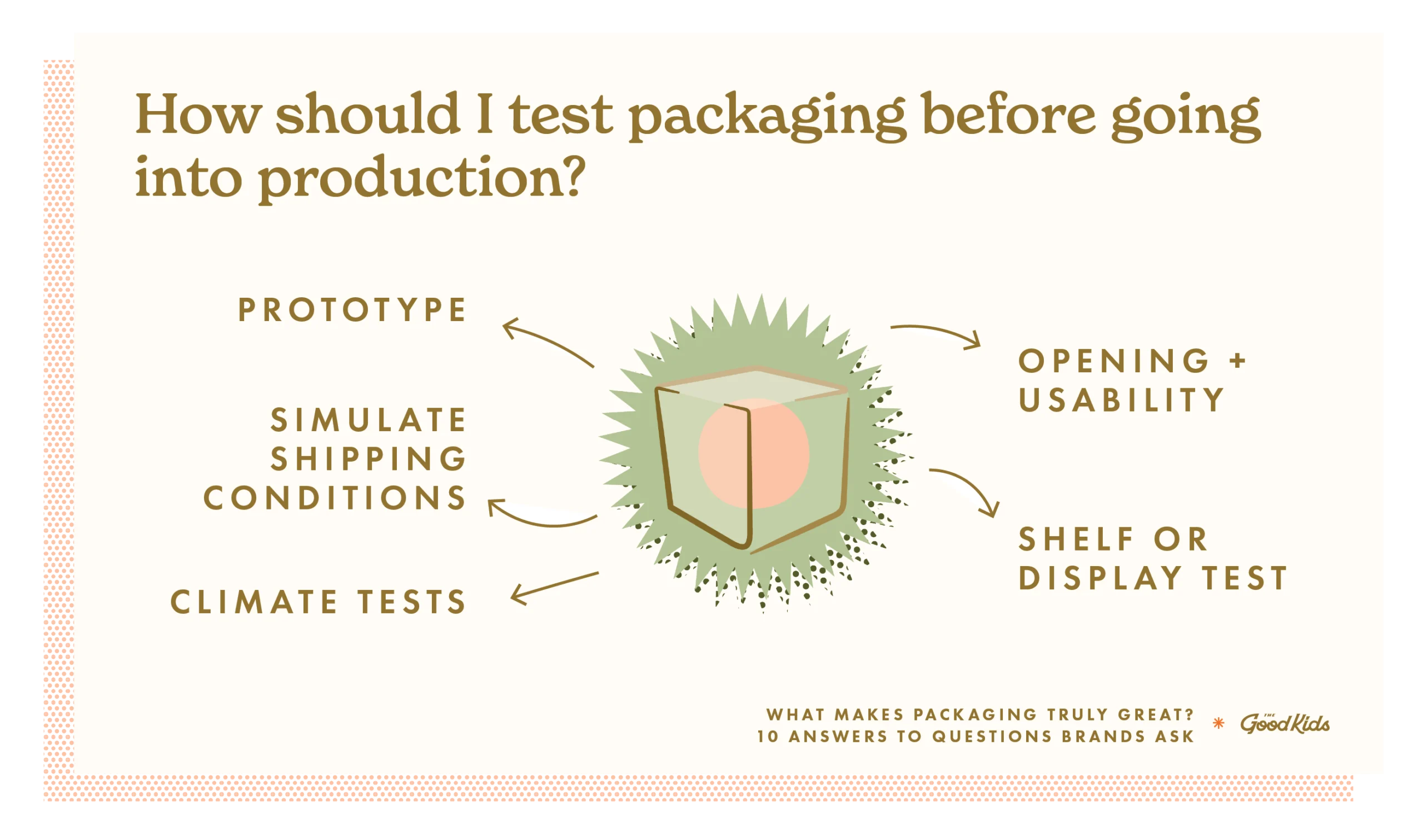

Testing early saves major headaches (and money) later. Here’s how to stress-test your packaging:

- Prototype: Build real samples, ideally full size and with your final materials.

- Simulate shipping: Drop, stack, shake, repeat. Mimic truck, air, and sea transit conditions.

- Climate tests: Expose it to heat, cold, and humidity swings. Does glue peel? Does it warp?

- Usability: Is it easy to open? Are the instructions clear? Does it feel good to handle?

- Shelf/display test: Check visibility from a distance, under various lighting, and against competitors. For e-commerce, make sure it photographs well at thumbnail size

Collect feedback from customers, fulfillment teams, and retailers, then tweak until you hit the sweet spot of protection, brand feel, usability, and cost.

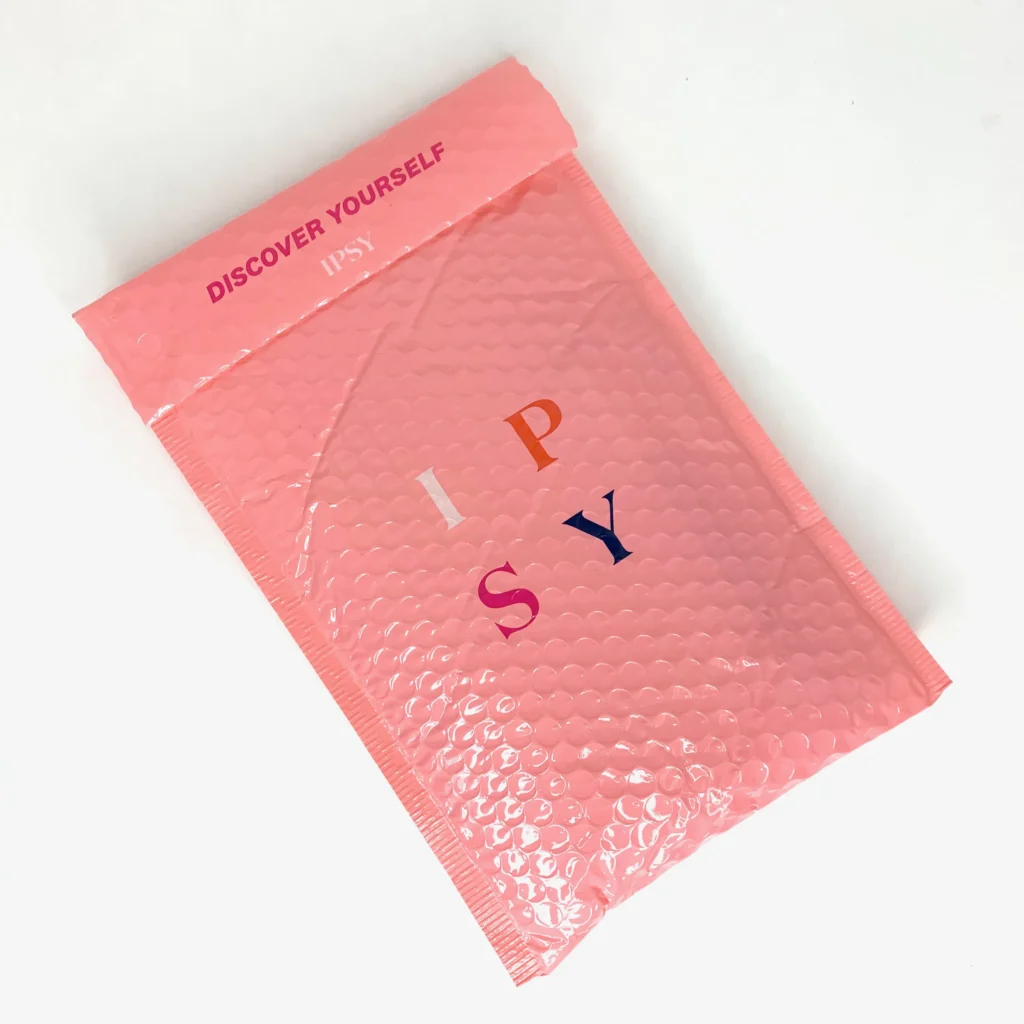

How can packaging drive marketing, unboxing & social buzz?

Packaging can (and should) be part of your marketing toolkit.

- Create unboxing moments with layers, reveals, or messages inside flaps; even simple touches can delight.

- Design for shareability. Eye-catching design, textures, and surprises get people posting on social.

- Tell your brand story. Include snippets about your origin, values, or ingredients; customers love brands with a heartbeat.

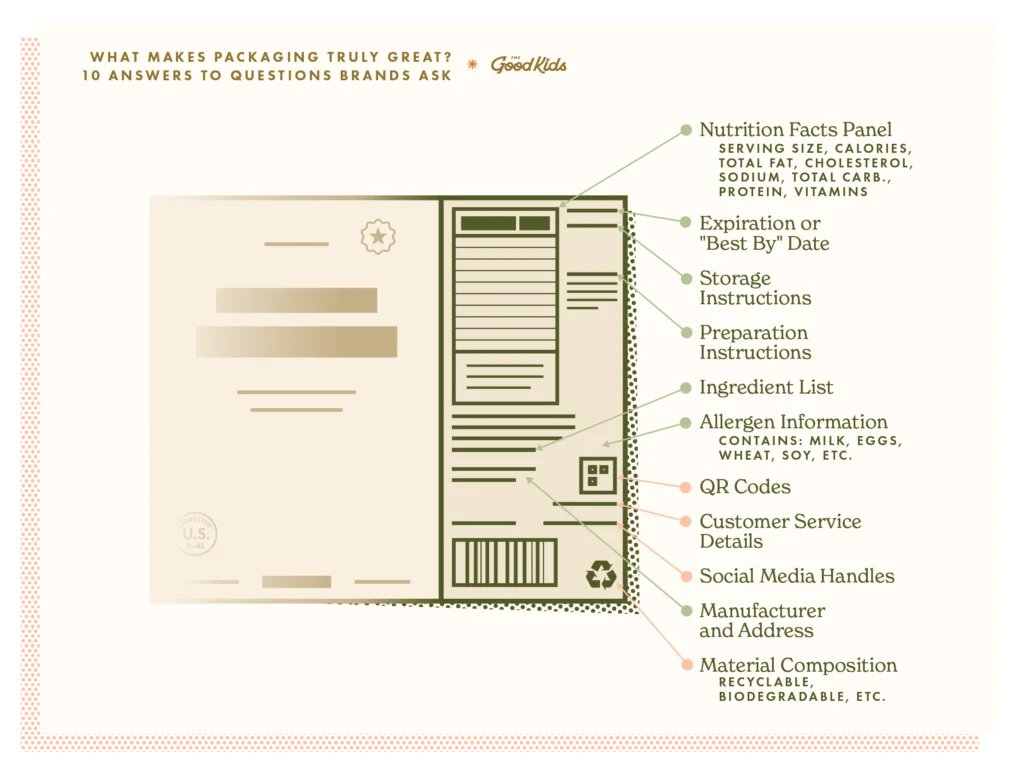

- Add digital touchpoints: QR codes, links to videos, story cards, or personalized notes can all extend the experience.

And above all, keep everything consistent, from product photos to shipping boxes. Every moment shapes perception.

There are many moving parts when it comes to packaging, whether it be the design, prototyping, regulatory requirements, etc.

The Good Kids are your ultimate packaging guide with years of experience and valuable connections to help your product’s packaging stand out, and fly off the shelves. If you have questions or you’re just not sure how to get started, drop us a line!

Summary Checklist

| Area | Key Questions to Answer |

| Protection | What are the physical/handling/climate stresses my product faces? Will my package survive shipping & storage? |

| Branding & Visuals | Does it reflect my brand identity clearly? Will it stand out among competitors? Is it legible and appealing both online & on shelf? |

| Materials & Sustainability | What materials are used? How recyclable / compostable / reusable are they? Do they introduce extra costs? |

| Cost & Logistics | What are the hidden costs (tooling, shipping, weight, labor)? Can I simplify or modularize? |

| Testing & Feedback | Have I built prototypes? Tested them? Gathered feedback from users and partners? |

| Regulatory & Regional Fit | Will it meet legal labeling / material regulations in target markets? Handling climate, disposal norms, cultural preferences? |

| Marketing & Experience | How will it feel to open? Can it drive social sharing? Does it tell a story or add delight? |

FAQs about Packaging

Q: How much extra should I expect to spend on high-quality packaging versus basic packaging?

It’s common for premium finishes, custom shapes, stronger materials, or eco-friendly materials to add 10-50%+ over basic packaging. It depends heavily on scale, material choices, and how many custom touches (die-cuts, embossing, inserts) you include.

Q: Can small brands still compete with excellent product packaging while operating on tight budgets?

Absolutely. Small brands often win by creativity: clever design, minimalism, upcycled materials, limited but meaningful details (labels, inner messages), or by focusing on what customers value most. Smart prioritization, and well-crafted branding is key.

Q: Does sustainable product packaging always cost more?

Not always. Sometimes sustainable materials are more expensive, but other times reducing material volume or switching to simpler designs offsets cost. Also, as demand for sustainable packaging increases, prices are lowering. When done well, sustainability can be a selling point that offsets cost via higher perceived value or customer loyalty.

Q: If I only ship via e-commerce and don’t do retail, should I design differently?

Yes. E-commerce packaging must survive shipping shocks, possibly rough handling, and look good when unboxed (photos, video). You might place less weight on shelf visibility and more on fit into mailers, protection, and minimizing wasted space.

Q: How important is packaging weight vs. size in shipping costs?

Very. Shipping cost is influenced by both weight and volumetric (dimensional) weight. Large bulky packaging (even if light) can incur high fees. Optimizing both size and weight can reduce shipping and handling costs significantly.

Q: What are common mistakes people make with product packaging design?

- Overpackaging: extra layers, unnecessary inserts.

- Under-testing: launching without simulating shipping or climate conditions.

- Ignoring sustainability or regulatory requirements, leading to unexpected costs or compliance issues.

- Design disconnects: what looks good on screen doesn’t translate to print or physical object.

- Neglecting user experience; if it’s hard to open, has unclear labeling, or is a mess when opening.